With their robust construction, handhelds and forklift terminals are designed for use in the rugged daily routine of warehouses or manufacturing. However, even mobile industrial hardware can become defective. In such a case, good service that ensures fast repair or replacement is valuable.

When procuring hardware for mobile data entry (MDE) projects, in addition to the fit of the mobile devices, their technical specifications, and prices, a look into the future also plays an important role: What happens if a device fails due to a defect? Two factors play a role in answering this question:

- The repair capabilities of the suppliers

- The maintenance contracts of the manufacturers

Repairs via the Supplier

When procuring mobile devices, the supplier's ability to handle maintenance and repairs is an important decision criterion. A capable supplier ideally has their own team that can carry out repairs promptly in the event of defective devices.

For example, GLOBOS Logistik- und Informationssysteme, based in Hanover, has a central workshop and a spare parts warehouse for maintaining, repairing, and exchanging defective hardware sent in. "Globos accepts hardware regardless of the manufacturer, which is often of benefit to customers," assesses Matthias Malinowski, Team Leader of Customer Service.

Regular maintenance of hardware, such as printers, is also part of the service spectrum of hardware suppliers in the logistics environment. Ideally, a supplier has regional service points to achieve area coverage and thus fast response times. "Fast on-site service can also be determined via maintenance contracts or service contracts with fixed response times and maintenance dates," informs Malinowski. If a fast exchange of hardware needs to be realized, a supplier can ensure this via so-called backup pools. "Basically, an on-site appointment is always possible the next day," explains the customer service manager, "however, this must be agreed upon in the SLA."

Free Guide

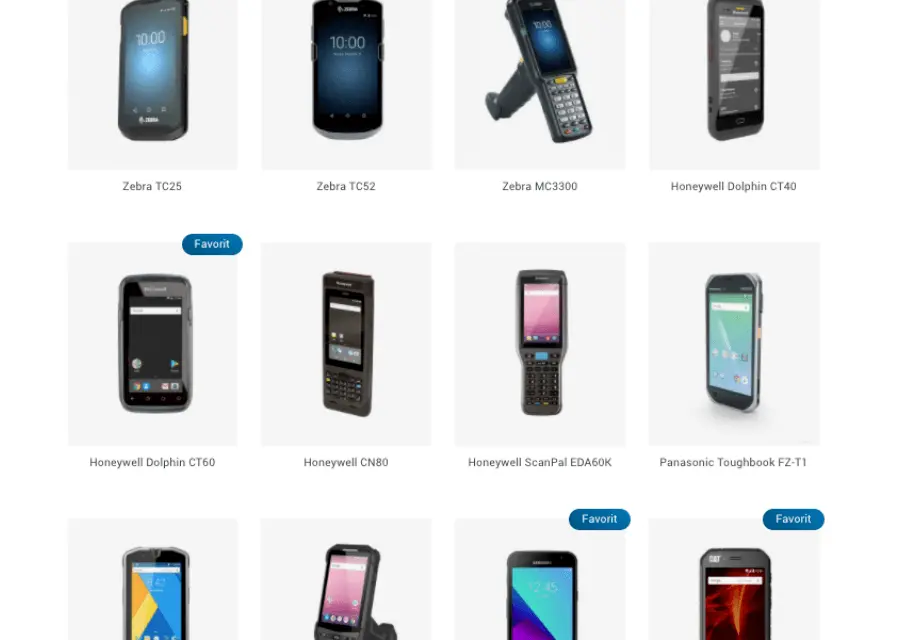

Use our Hardware Finder to choose the right mobile device.

Repairs via Maintenance Contracts with Manufacturers

Technical and telephone support is the foundation of every customer service. However, this service differs primarily in the response time and the scope of maintenance and repair included in the standard contract. Manufacturers often offer tiered contract models with special service features. However, some manufacturers also choose the path of offering a standardized service contract with a high scope of service. The following examples of maintenance models from various manufacturers illustrate these different service approaches.

Examples of Maintenance Models from Hardware Manufacturers

Zebra

Zebra offers various maintenance plans and service contracts under the keyword OneCare:

- Zebra OneCare Special Value (cost-effective protection): Software/phone support, repairs within 5 days, optional coverage for accidental damage

- Zebra OneCare Essential (basic protection): Repairs within 3 days, software and security updates, phone support

- Zebra OneCare Select (increased protection): 24/7 support/phone support, repair and fully configured device replacement the next day

- Zebra OneCare Support On-Site: Option for hardware not suitable for shipping, service within 1 or 2 business days

Honeywell

The configurable service contracts offered by Honeywell are as follows:

- Basic Warranty Plan: Cleaning, preventive maintenance, telephone/technical support, warranty services such as extensions

- Gold Maintenance Service Plan: Limited exchange depending on region, repair within 2 business days, cleaning, preventive maintenance, telephone/technical support

- Platinum Service Solution: Device and accessory exchange, repair within 1 or 2 business days, cleaning, preventive maintenance, telephone/technical support

Keyence

For the basic service offering provided by Keyence, customer service and repair contracts follow a standard model. This includes the following services:

- Repair/Free loaner devices

- Return shipment on the same day aimed for (depending on time of day)

- Telephone/technical support

- Product training and after-sales support/setup or commissioning

Conclusion

Problems and defects can occur with handhelds and forklift terminals during live operation. Therefore, it is good to have an overview of which hardware and which partner one wants to proceed with into the future. An important decision here is whether repair contracts are concluded via the supplier or the manufacturer. In the case of a service contract via the supplier, it must be noted that they also possess the corresponding repair capabilities and accept hardware as independently of the manufacturer as possible. In the case of manufacturer-side customer service, the offered contract models must be examined closely regarding which response time and scope of service they contain.

Checklist

Check with these 10 points whether your mobile apps already have excellent UX.

.webp&w=3840&q=75)