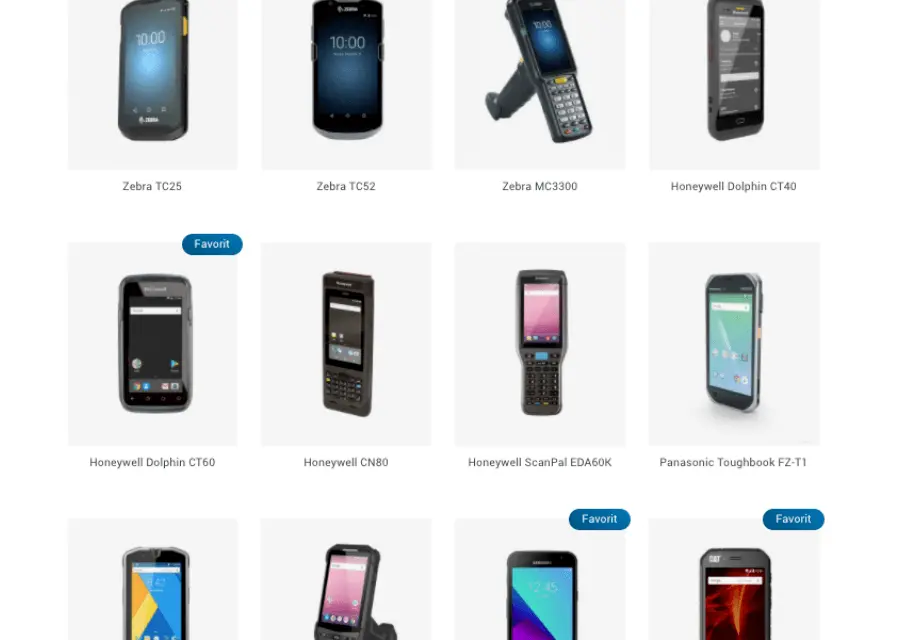

In today's SAP warehouse logistics, a wide variety of mobile devices are used. Industrial handhelds and forklift terminals are among the most common devices, supplemented by handheld scanners, glove scanners, or smart glasses. This guide explains what to consider when selecting suitable handhelds or terminals for MDE projects.

6 Relevant Selection Criteria for Mobile Devices

- Battery

- Ruggedness

- Touch Screen vs. Keyboard

- Barcode Scanning

- Data Connection

- Mobile Operating System

The Battery: Standard, Extended, and Hot-Swap

For efficient use in shift operations, the battery performance of a mobile scanner device is crucial. Battery life depends on many parameters, such as the software being used, which hardware functions are utilized, or how long the display is active at full brightness.

As a general rule, the higher the quality of a mobile device, the better the battery performance offered by the manufacturers. Anyone dependent on smooth operation should look for the ability to change the battery during operation, known as hot-swap or use optional, more powerful battery variants.

The Operating Environment: How Rugged Does the Mobile Device Need to Be?

.webp)

The specific location of use plays the decisive role in determining how rugged a mobile device needs to be for warehouse operations.

- For example, it makes a difference whether work is done indoors or outdoors, under artificial light or sunlight. The latter is more likely to cause disruptive reflections, placing special demands on the display.

- In hazardous material environments, explosion-proof devices are a must. In the healthcare sector, mobile devices should be resistant to disinfectants. When used in cold storage, it is important that the display does not condensate, which would hinder work.

- By default, most devices are shock-proof and splash-proof. The temperature range in which devices are operational is typically between -10 and +50°C.

The criteria mentioned provide clues for asking the right questions during hardware selection. Another factor should not be forgotte ruggedness comes with weight. In harsh environments, heavy, perhaps even "bulky," mobile devices are advantageous; for small parts picking, a simple industrial handheld is often sufficient.

Operation: Touchscreen vs. Keyboard

The vast majority of mobile computers for use in intralogistics are delivered today as touch-only devices. However, devices with a physical keyboard, i.e., classic hardware keys in various configurations still exist.

Practice shows that employees appreciate the smaller size of touch devices and their usually larger displays. They are used to handling touch screens and expect a modern work tool. It is important to rely on optimized software keyboards and not the standard pre-installed operating system keyboards.

Practice shows that employees appreciate the smaller size of touch devices and their usually larger displays. They are used to handling touch screens and expect a modern work tool. It is important to rely on optimized software keyboards and not the standard pre-installed operating system keyboards.

A physical keyboard can also have its merits. If work is primarily done with gloves or if chemicals are frequently used, a hardware keyboard or a modular keyboard is indispensable.

Optimal Barcode Scanning: Selecting the Right Imager

The optimal scan technology in a warehouse environment is usually quite easy to determine: an integrated imager should be used. But be careful: there are differences between devices and even within a single model's configuration. Unlike older laser scanners, most devices today use so-called imagers (camera scanners), which can also read information-rich 2D codes, such as QR codes.

.webp)

The selection of imagers is large:

- Touch Reader: up to 5 centimeters

- Short Range: up to 1.5 meters

- Standard Range: 90 centimeters to 6 meters

- Long or Extended Range: 15 – 21 meters

A Note on the Camera

Can an integrated camera also be used for scanning? In principle, yes, but... the integrated camera scans very slowly and is therefore only recommended for a few scans per day.

However, using the camera is interesting in other respects. The camera can be used to document delivery slips or damage during goods receipt. Furthermore, modern scanner software can use text recognition (OCR) to read, for example, delivery slip numbers, thus noticeably speeding up work processes. Such special cases should therefore be taken into consideration.

Data Connection via Wi-Fi or Cellular

In indoor areas, Wi-Fi (Wireless LAN) is used almost exclusively for communication between mobile devices and the enterprise resource planning (ERP) system, e.g., SAP. In outdoor warehouses or on very large company premises, complete Wi-Fi coverage is often lacking. In that case, cellular technology is a real and affordable alternative.

A special case: What to do if there is neither Wi-Fi nor cellular access in basements or when loading goods into containers? In these situations, an offline option in the scanning software can help ensure smooth operation.

The Mobile Operating System: Android vs. Windows vs. iOS

Android is the leading mobile operating system for mobile hardware in intralogistics, having practically replaced the long-dominant Windows operating systems. Windows as a mobile OS is still used on special terminals or tablets.

Apple devices (iOS) are practically never used in the industrial sector. Only in maintenance or field service, where aspects like ruggedness or scanning capability play a subordinate role, are iPads or iPhones regularly used.

Conclusion

The criteria summarized in this short guide provide a starting point for your own hardware selection. Experience shows that it is always helpful to test different mobile devices, if possible, in combination with the planned scanner software. IT or warehouse managers should always involve the employees in the decision-making process for scanner hardware. After all, they are the ones who will ultimately work with the devices, and the success of a mobile scanner solution depends on their acceptance.

Free Guide

Use our Hardware Finder to choose the right mobile device.

.webp&w=3840&q=75)

.webp&w=3840&q=75)