Poka Yoke in production stands for strict quality specifications. The principle can be integrated seamlessly into mobile data capture with SAP. In this way, supplier companies can transparently implement the requirements of automotive manufacturers.

Strict Quality Specifications from Automotive Manufacturers

The automotive industry is known for its very detailed and strict process and quality requirements. These apply in their own plants but are simultaneously demanded from suppliers. In process reviews or Layers of Protection Analyses (LOPA), OEMs like BMW audit processes in production and warehouse logistics together with the supplier and implement optimizations where necessary.

Error Prevention in Manufacturing

One OEM requirement concerns transparent, traceable, error-free process steps in manufacturing that are booked in SAP. Standard bookings related to production orders include material staging as well as partial or final confirmation of orders. Manufacturing itself and its individual steps can also be secured via MDE processes and this is often required by OEMs. Furthermore, practice frequently necessitates specific mobile processes, for example, when customer-specific requirements need to be considered.

In our application example, the Poka Yoke principle comes into play here: Strict technical specifications—including mandatory inputs on the MDE device—are intended to prevent errors in the production of plastic injection molding parts.

Poka Yoke and Mobile Data Capture

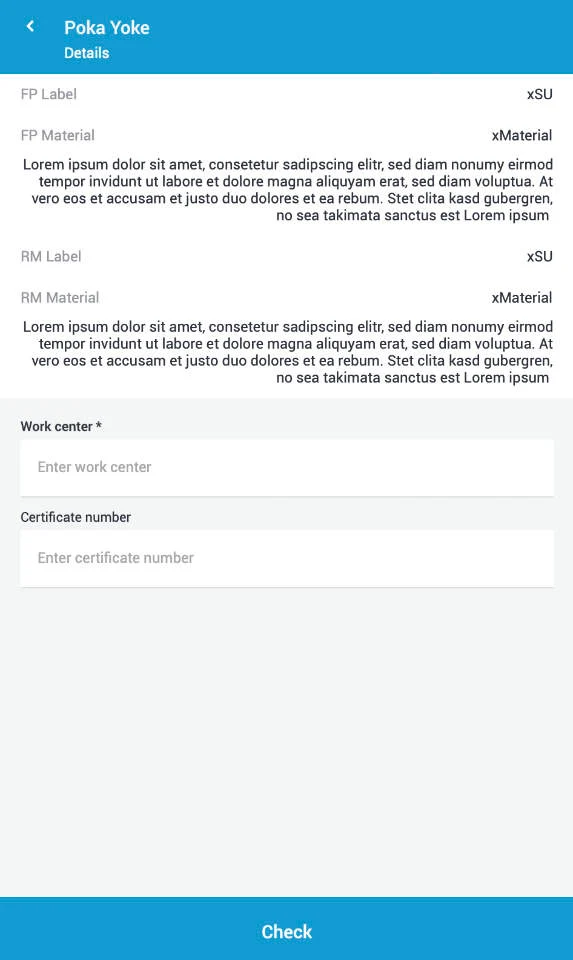

In our first example of a Poka Yoke process, the processing of production orders is guided via mandatory control scans:

- 1. Scan of a Finished Goods Label to uniquely identify the finished part to be produced.

- 2. Subsequently, the container with the raw material is scanned.

- 3. Capture of the barcode at the workplace (here an injection molding machine).

Fig. 1: Identification of the finished part via scan of a Finished Goods Label

The captured data is transferred to SAP, in this specific case to a Z-module for the Poka Yoke process. Only after positive feedback is sent to the MDE device is production allowed to begin.

OEM-Specific Variation of Poka Yoke: Production Material Check

A variation of the guided production process is shown in the second example, which was used to implement the requirements of an automotive OEM.

Here, too, manufacturing is mapped via three separate work steps to be booked via mobile device.

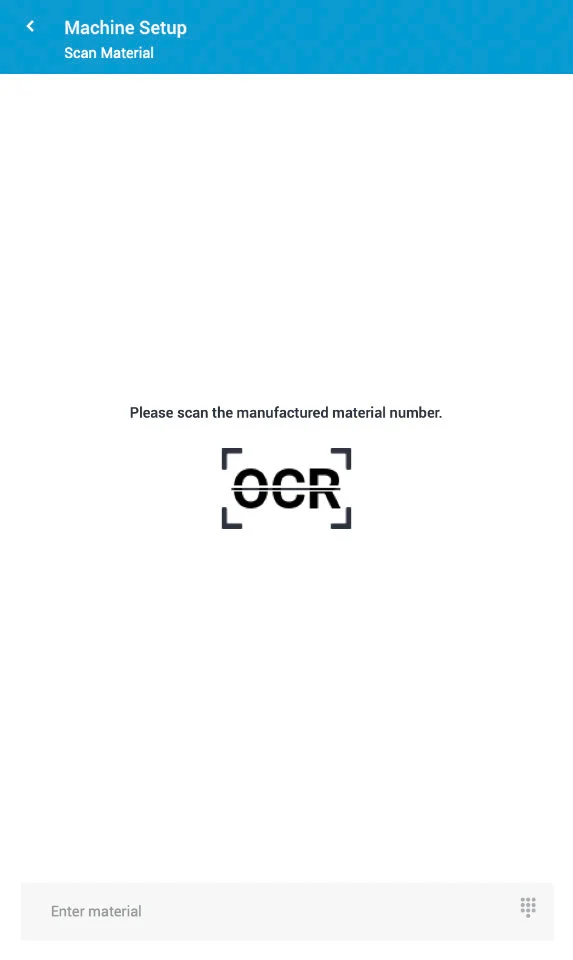

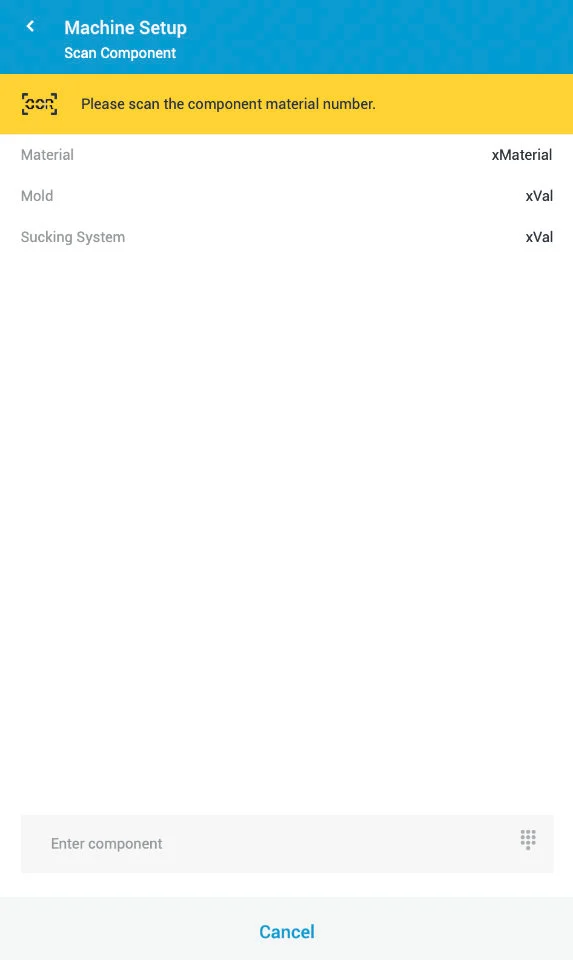

- 1. Machine Setup: The work preparation steps are documented in detail via scan. This includes the scan of the workplace, the capture of the reference number (of the finished part), the suction pump used, the granule ID, and the ID of the granule container. If the setup corresponds to the SAP-side specifications, a corresponding entry is created in SAP, and production can begin.

- 2. Refill Bin: Granule supply at the machine takes place via containers secured with an electronic lock. To open the lock, the employee first scans the source container from which material is taken. Then the container at the machine is scanned. The scanning app then generates a barcode that is read by the container lock—the lock opens.

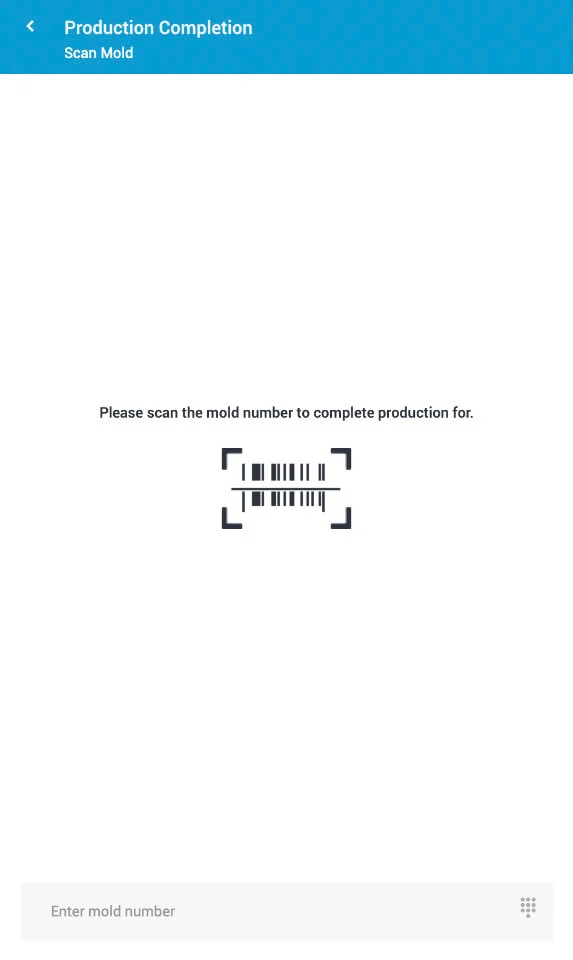

- 3. Production Completion: The documentation of manufacturing is concluded with the confirmation, which takes place via an ID scan of the workplace.

Fig. 1a Machine Setup: Capture of the reference number of the finished part

Conclusion

SAP production processes can be mapped very granularly and, above all, individually adapted in a scanner app. Through strict scanning specifications, production processes are safeguarded against errors, and the individual manufacturing steps are documented transparently in SAP.

Know-how

Speak to an expert in mobile data capture in SAP logistics.