Digital, paperless order picking with direct SAP integration is a daily reality in many companies. For man-to-goods processes, handhelds with logistics apps are often used. Using back-of-hand or ring scanners offers additional optimization potential.

SAP order picking is one of the core logistical processes. Regardless of the specific context for example, during material staging for a production order or bill of materials, or picking for delivery or transport, the manual steps from the warehouse employee's perspective are comparable. The underlying order contains the relevant information, such as:

- Storage location

- Storage bin

- Item description and item number

- Quantity

- Batch, serial numbers, etc., if applicable

The challenge is to optimize picking performance while simultaneously achieving a minimal error rate. Using mobile data capture in order picking is one way to optimize processes. Data from the process is captured in real-time by the warehouse employee via a handheld scanner, transmitted, and updated in the SAP system, which improves the efficiency and accuracy of picking. This seamless integration of hardware and software also enables effective control and monitoring of logistical processes.

By combining MDE devices with wearable technology, efficiency can be increased even further.

What Are Back-of-Hand, Glove, or Ring Scanners?

Wearable scanners are portable devices attached to the back of the warehouse employee's hand or finger and are used to capture data, such as barcodes, QR codes, or Data Matrix codes.

- A typical back-of-hand scanner consists of a small, lightweight unit attached to the user's hand or finger (ring scanner).

- The device is equipped with a scan module that captures data using a laser or an image sensor.

- Scanning can be triggered by a simple tap or press.

- Scan ranges: from a few centimeters to several meters.

- The wearable scanners are offered with various interface options such as NFC, Bluetooth, or Wi-Fi to enable seamless integration with other systems, e.g., a handheld device.

SAP-Integrated Order Picking

From a technical perspective, back-of-hand scanners show their strengths when used together with an intelligent MDE device. The device gets its "Intelligence" in the form of a picking app. This app, e.g., based on the Ontego platform, processes the information captured by the wearable scanner and reports it back to SAP inventory management or warehouse management - SAP WM, SAP EWM, or SAP Stockroom Management - according to a defined logic. This gives employees in the logistics office or logistics managers real-time information about inventory, the progress of order picking, and other relevant data

The Market for Back-of-Hand Scanners

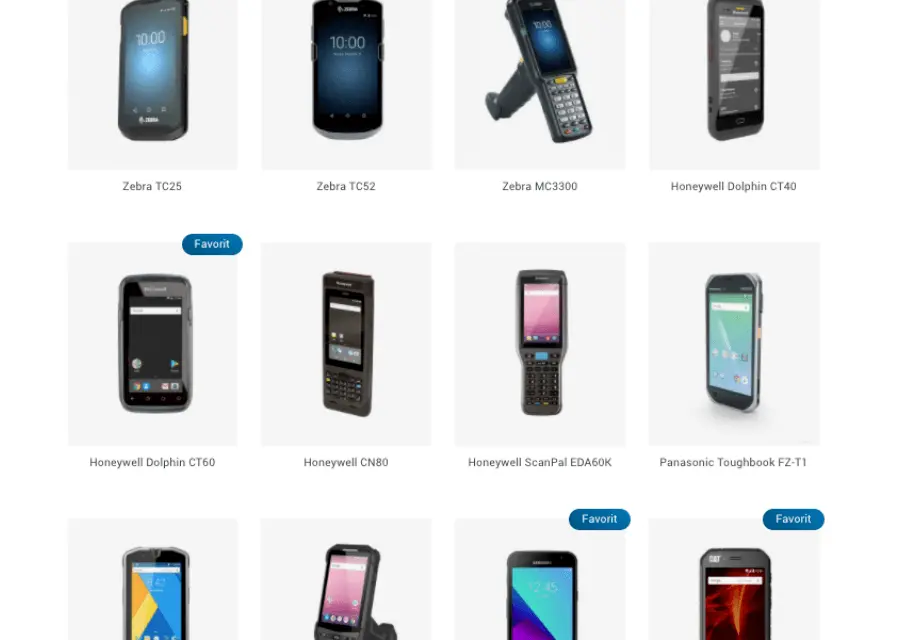

Back-of-hand scanners now complement the portfolio of all well-known manufacturers of industrial handheld hardware, including the market leaders:

- ProGlove

- Zebra Technologies

- Honeywell

These manufacturers are just a few examples, and there are other companies that offer wearable scanners, such as Datalogic, Point Mobile, or the German providers ACD and Feig Electronic.

Free Guide

Use our Hardware Finder to choose the right mobile device.

How Order Picking with an SAP App and Glove Scanner Can Work

Using a logistics app like Ontego on a handheld device in conjunction with a glove scanner enables an efficient and accurate order picking process.

- Preparation: The picker logs into the logistics app on the handheld or forklift terminal with their SAP credentials to start the picking process. The MDE device is connected to the glove scanner and ready for use.

- Order Selection: The picker selects an order picking job in their logistics app. The order contains information about the products to be picked, the storage location, and other relevant details.

- Picking: The picker starts the picking process in the app. The order items are displayed to them in the sequence specified by the SAP system. They walk or drive to the designated storage location or bin.

- Scanning the Barcode: Using the glove scanner, the picker scans the barcode of the selected product. The scanner captures the barcode automatically and transmits the data to the logistics app on the MDE device.

- Confirmation of Picking: The barcode scan also serves as the confirmation for the respective order item.

- Continuing the Process: The next item opens in the app, and the picker repeats steps 3 and 4 for the remaining items in the order.

- Completing the Order: Once all products for the order have been picked, the picker reports the completion of the order via the logistics app. The information is transmitted to the higher-level system, such as an SAP system, to update inventory and progress.

The handheld device and the glove scanner allow for seamless capturing and confirmation of products while the picker handles the goods. The integration of hardware and software improves productivity, reduces errors, and enables real-time updating of inventory and order information.

Advantages of Glove Scanners in Order Picking:

The use of back-of-hand scanners in conjunction with handheld-based logistics apps offers several noteworthy advantages:

- Speed: Thanks to hands-free operation, employees can directly pick goods or materials from the storage bin and pack them onto a pallet or into a small load carrier (KLT). The usual need to reach for a handheld or hand scanner is eliminated. A time saving of several seconds per scan is achievable.

- Ergonomics: Glove scanners are ergonomic, weigh only a few grams, and are easy to use. This reduces physical strain and fatigue for warehouse employees.

- Intuitive Work: Order picking processes supported by glove scanners are simple and easy to understand. New employees are trained quickly and become productive immediately.

Logistics managers interested in specific figures on savings potential can find them from manufacturers or in studies. For example, the pioneer in the industrial wearables market, Workaround GmbH (ProGlove), states a time saving of up to 6 seconds per scan on its website. In a study, the Fraunhofer Institute for Material Flow and Logistics (IML) determined that picking time can be reduced by up to 35%.

Conclusion

Back-of-hand scanners can simplify and accelerate order picking. In combination with logistics apps, wearable devices minimize errors and speed up work processes, leading to higher picking performance. For logistics managers, it may be worth considering calculating selected processes using glove scanners, especially with employee satisfaction in mind.

Know-how

Speak to an expert in mobile data capture in SAP logistics.

.webp&w=3840&q=75)